Cost Savings

Arteis Technology

An Artesis motor control module can hook up to any three phase motor and learn the motor within a short time period. Once it understands the motor it will automatically determine any issues with the motor electrically and mechanically.

Some examples of what it can determine are the following:

- Mechanical Faults – unbalance, misalignment, roller bearings

- Electrical Faults – loose windings, short circuits

- Process Faults – cavitation, plugged filters and screens

The motor module will tell you the severity of any faults and give you a estimated time of failure if maintenance is not performed.

However determining faults within motors isnt the best service the motor module offers. The best part is that this motor control module is a continuous conditioning monitor system. Once installed in the motor control system it is continuously reporting the health of the motor which enables you to predict maintenance and any unplanned down time saving a fortune to the facility.

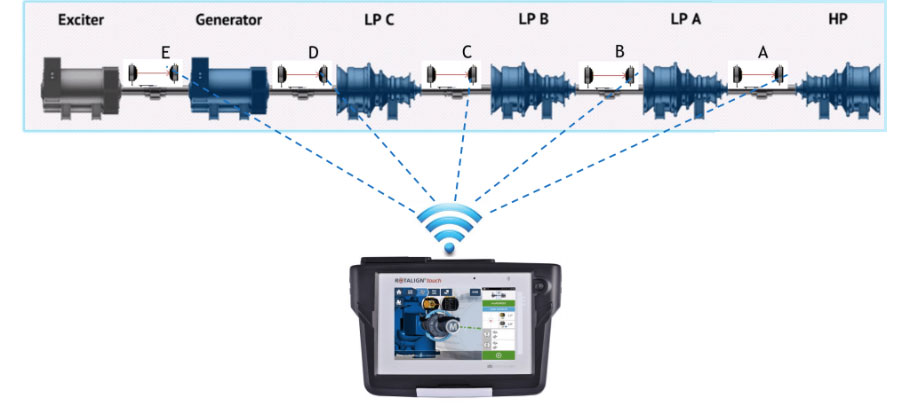

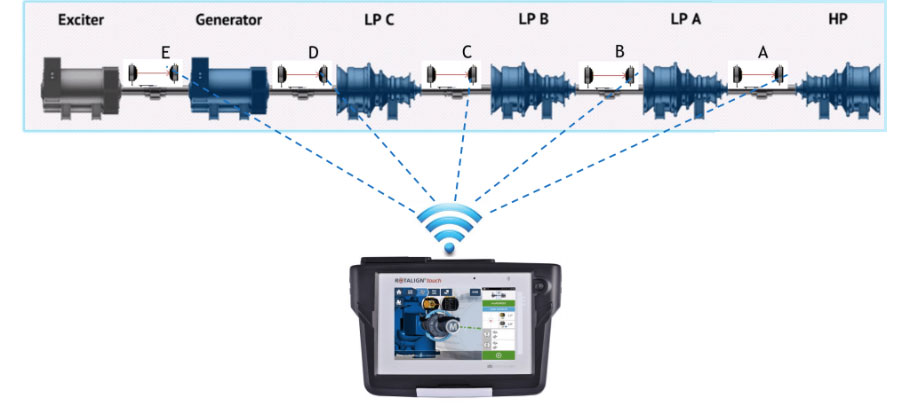

Static Shaft Alignment

Align your rotational equipment without rotating it!

Current methods of using dial indicators are extremely time consuming and non labor efficient. Even the traditional laser alignment requires the system to be in service before alignment.

Now with new technology we have the ability to align your equipment without rotating it. It allows you to save countless outage hours awaiting your equipment to be returned to service.

Just imagine having your equipment aligned and ready for service even before it is tagged back into service.

Not only do we have the ability to align it without rotation but we have the ability to align multiple couplings simultaneously.

We have the ability to prove new alignment technology to save you an incredible amount of outage time.